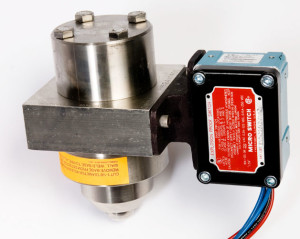

Maloney Series III Detector

Long LifeStandard and NACE ModelsHigh Reliablity

The Maloney Series III Detector is a mechanical plunger-style detector manufactured for use in both conventional pipeline and meter prover services. This rugged detector is known as the “work horse” of the industry. It is field proven to survive in adverse conditions.

Features

BIDIRECTIONAL DETECTION

When centered on top of the pipe, a spherical radius probe allows detection from either direction with equal response.

WIDE PRESSURE RANGE

To provide pressure balancing, holes are drilled through the shaft to equalize pressure across the seals. The standard detector can be used in all operating pressures up to 1440 PSI.

EASY OPERATION

A U-type, Teflon® with stainless-steel spring inserts maximizes shaft sealing and minimizes resistance to shaft-to-seal friction.

NON-ADJUSTABLE DETECTOR SWITCH for meter prover service. Sealed to insure an accurate setting, the microswitch trips within .001 inch of a predetermined point. The sealed switch also eliminates the need for recalibration after replacement.

CORROSION-RESISTANT PARTS

Stainless steel is used for all metal parts, (except the scarfed welding base), to retard resistance to wear and aging. Unless otherwise specified, a carbon-steel welding base is provided to maximize weld compatibility with standard carbon steel pipe. As an option, the Series III Detector can be manufactured of sulfide-stress-cracking resistant stainless steel to meet the requirements of NACE MR-01-75.

MULTIPLE ACCESSORY FLEXIBILITY

Two accessories can be mounted on the standard, two-port, square accessory plate, with special four-accessory models available on request. Accessories are activated by a cam on the probe shaft.

SIMPLE INSTALLATION

To prevent welding heat from damaging the seals, the top of the detector assembly is disconnected from the base by simply removing the four hex-head bolts which secure the assembly to the base. A 1-1/8″ -inch hole is then cut in the top of the pipe. Then the base is centered and welded into place.

Note: Where more than one detector is being installed for pipeline service, care should be taken to remount each detector assembly on the same base with which it was shipped.

The Series III Detector cannot be removed while under pressure.

Please refer to Downloads section for component identification and replacement part numbers.